Wake Stone Corporation

Wake Stone Corporation was founded by John Bratton Jr. His whole professional career in the mining industry produced the desire to have one quarry of his own. In 1970, he took that chance. Along with his eldest son, Johnny, they built the foundation of a family business that has lasted over fifty years. Currently with five locations in North and South Carolina, and seven members of the family employed, John would be proud of the family business he started. He would be particularly proud of the company staying true to the mission and principles upon which he started the business.

At Wake Stone, our quality stone products and unparalleled customer service are what we do every day. Whether you are building a highway, an office building, a shopping center, a school, a hospital or a home, you need quality crushed stone; and we are proud to always have what our customers need. The loyalty of our thousands of customers is very gratifying. Our 200+ employees have an average tenure of over 15 years with the company. We count on that to do what we do better than our competition. And we are proud of our track record in environmental stewardship, regulatory compliance, safety, and giving back to the community.

Please follow our timeline below for a walk through our past.

Or visit the quarry location pages to read the history of each of our locations.

We are proud to have begun real estate development in 2015 in Knightdale.

Or go to our Community Page and see how we give back.

Thank you for your interest in Wake Stone Corporation.

Mission and Values

Mission

At Wake Stone our mission is to supply the building blocks of our communities, providing superior products and personalized service for our loyal customers, while prioritizing environmental stewardship and the well-being of our dedicated employees.

Values

Over 50 years ago, John Bratton founded Wake Stone Corporation on two core values: being good stewards of the land and being good neighbors. Wake Stone remains committed to these important values today.

Every decision we make is made with the surrounding community in mind, from the design of quarry entrances and offices to the placement of vegetative berms and visual buffers.

We believe being a good neighbor also means an unwavering commitment to reclamation, restoration and beautification.Thoughtful land management, careful attention to detail and incorporation of the latest technologies for environmental protection are just some of the ways Wake Stone excels at keeping the air and water clean and free of contaminants. The company has a long history of building and maintaining attractive facilities whether they are viewed from the outside or the inside. At Wake Stone, every effort is made to not only meet, but exceed the requirements of government regulations for environmental compliance and safety. It’s the Wake Stone way.

WHAT SETS US APART?

At Wake Stone, we are passionate about what we do, the communities we serve and the environment we work in.

Our Story

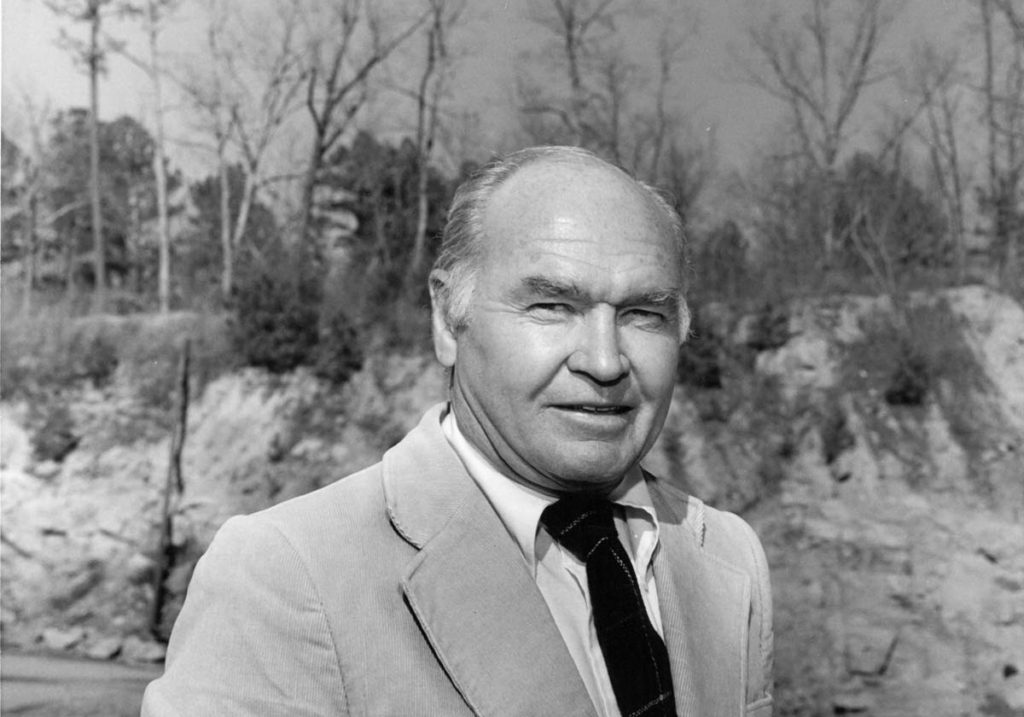

1970 – Wake Stone Founded by John Bratton

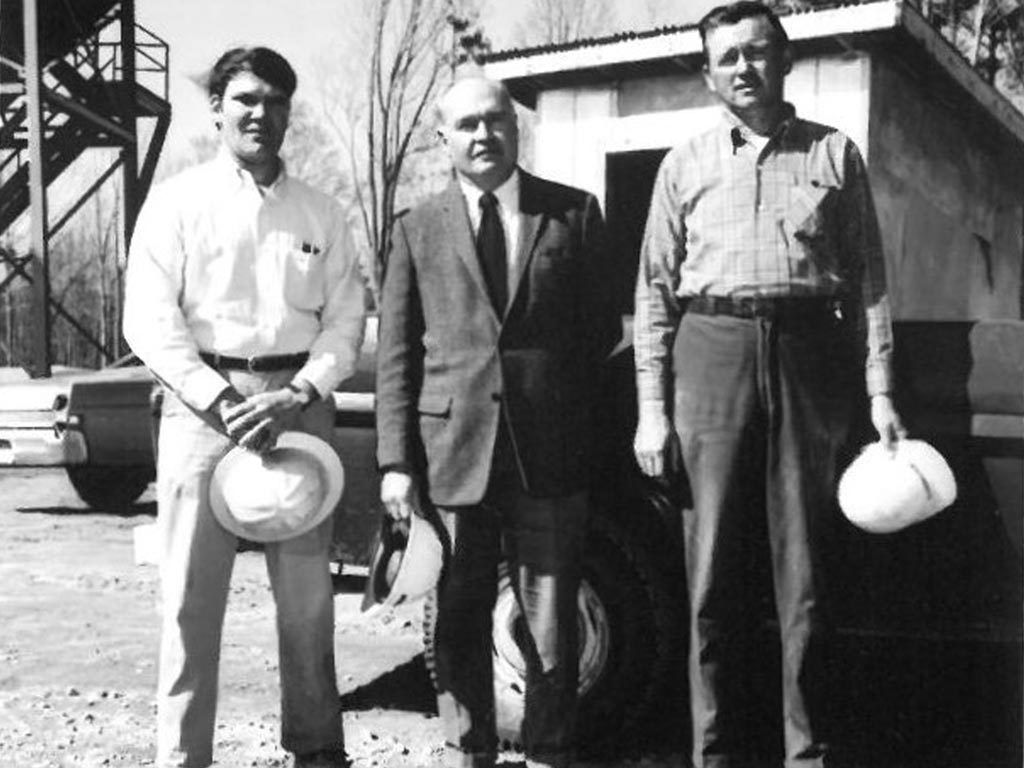

On April 1, 1970 John Bratton, Jr. started his dream. He had majored in Civil Engineering at State College in Raleigh, and played on the football team. WWII interrupted his college career, so as a U.S. Marine, he completed his engineering degree and was sent to China to build roads and bridges. When he returned to Raleigh in 1946 he joined Superior Stone where he rose through the ranks to Vice President of Operations. In that role he traveled the southeastern U.S starting more than 25 quarries. He came to the realization that all he wanted was one quarry of his own. And in 1970 at age 47, with just $50,000, he started Wake Stone Corporation. He had found 100 acres that was just right. All he needed was a few men to help him build a quarry. He pulled his eldest son, Johnny, out of college, hired a business manager, Duncan McCormick, and an experienced quarry man, Ronald Bissette, and started his own quarry.

1970 – Outlasting the Competition

With just a few employees, John Bratton and son, Johnny, set to work starting the new operation. By September 13th of that year, rock was being crushed and ABC available for customers…at the price of $1.50 per ton! But it was not as if Superior Stone (later Martin Marietta) was welcoming to the new competitor. In competitive industry fashion, they re-opened an abandoned quarry immediately adjacent to the 100-acre site and were open for business before Wake Stone. When John Bratton was planning his company, there were two long-time friends who promised that if he started his own quarry, they would stick with him even when things got tough. Bill Henry of Ready Mixed Concrete Company and John Holding of Carolina Ready Mixed Concrete were true to their word, and despite pressure from other providers, they stuck with Wake Stone. To this day, those two companies remain in our top ten customers every year.

1971-1973 – The Early Years

In 1970, the Town of Knightdale was a crossroads, way out in the rural area of Wake County. Fifty years later, it is a community of nearly 20,000 residents bounded by interstate highways and loaded with commercial development. The Knightdale Quarry entrance looked then like a peaceful farm. But peaceful was not a good description for the quarry company; surviving was. John Bratton lead, Johnny Bratton was the salesman and plant foreman, Ronald Bissette ran the quarry, and Duncan McCormick collected from customers, paid employees, and saved money…no one’s job was easy, and very long hours was the rule. The Company survived and built the reputation of being that reliable supplier of crushed stone to contractors, and asphalt/concrete producers.

1974 – Moncure Quarry Opening

Nuclear power was coming to the area. Carolina Power & Light was building their first nuclear power plant on a site in southern Wake County and needed one million tons of crushed stone for road base and concrete. Through a public bidding process, Wake Stone won out over much larger competitors to provide the stone. The contract required delivery by a fixed date of significant amounts of state specification product. All John and Johnny Bratton had to do was find a new location within 10 miles of the CP&L site and get it open and in production fast. Somehow, they pulled it off, and the Moncure Quarry began with Johnny Bratton as its superintendent. Opening Moncure led to the Company achieving its first million-ton year. The Shearon Harris nuclear plant was designed as a four-reactor plant. In the late 1970’s, after the Three Mile Island nuclear disaster, those plans were changed to a one-reactor site, and the contract with Wake Stone was wound down. In 1978, Ted Bratton, Johnny’s younger brother joined the family business in production.

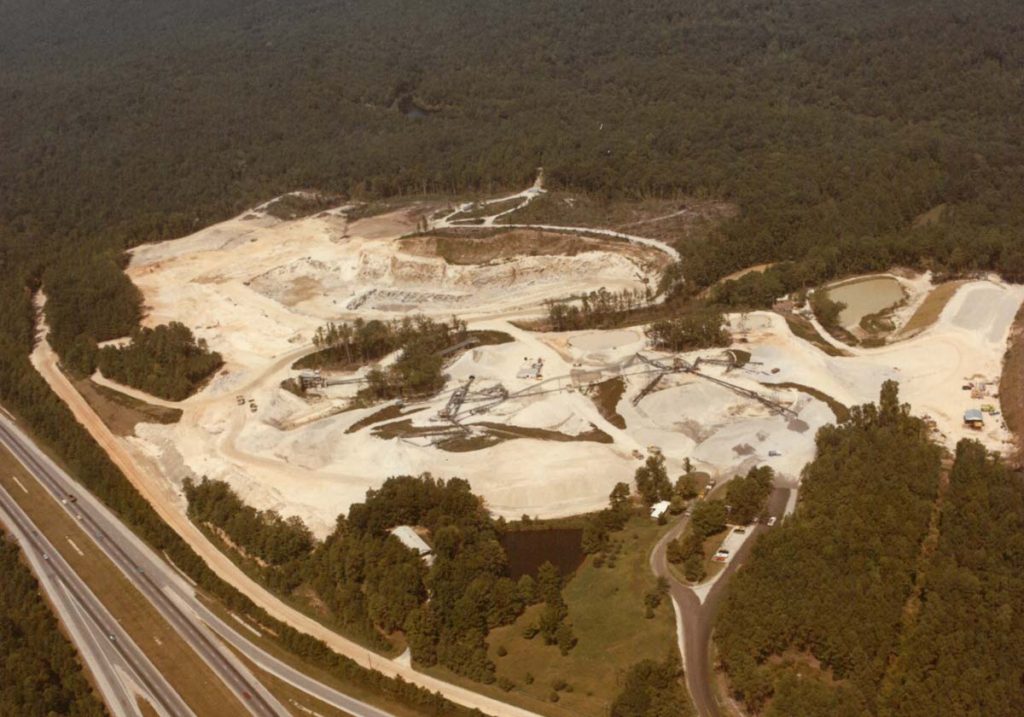

1979-1982 – Closing Moncure and Opening Triangle Quarry

While CP&L was considering reducing the scope of its expansion, John Bratton was looking for another site in Wake County. With the help of attorney Tom Adams and real estate broker Chuck Wachtel, Wake Stone lined up options on nine parcels totaling 220 acres on Interstate 40 near RDU Airport. By the 1980’s no quarries were easy to open: the State had a Mining act (1971) and zoning was county-wide in Wake. Of Wake Stone’s five quarries, none presented a greater challenge to open than the Triangle Quarry. The parcels were adjacent to RDU Airport and Umstead State Park. Everyone was concerned as to whether a quarry could operate there without damaging the serenity of the state’s largest Park. Politics reared its ugly head as various elected officials and boards took positions in opposition or in favor, right up to the Governor’s office. Eventually, after a court case on zoning and a Mining Commission hearing, a state mining permit was issued with numerous precautions to protect Umstead. The quarry started in 1981 using the relocated equipment and crew from Moncure Quarry, which had shut down after meeting the needs of the nuclear plant that same year. In the 38 years since, over 50 million tons of stone has come out of that quarry and been used within 15 miles for our growing community. And there have been no complaints registered with the State since 1985 (until the announcement in 2019 of the opportunity to expand the quarry onto RDU Airport land – see 2019 below).

The Roaring 1980’s

The early 1980’s were some difficult times. Oil shortages, high inflation, recession, the savings & loan crisis, and soaring interest rates as OPEC wreaked havoc with American businesses. In 1982, John Bratton bought out his only investor after 10 years. By 1983 he was confident enough in the future of his company to really give back to his employees. In 1983, the Company added a no-premium health plan for employees and their families. And we began our first ERISA retirement plan to share the profits of the company. The opening of Triangle Quarry proved better than forecast, and as the recession ended in 1984 the area economy took off. When American Airlines announced that RDU Airport would become its next hub in 1986, the Triangle area started its time of accelerated growth. Company sales in tonnage doubled from one- to two-million tons per year and higher which lasted through the end of the decade. And in 1987 Sam Bratton, the third second-generation brother, and in 1988 Al Parker, Jr., the first of our third-generation ownership joined the family business.

1988/89 – Reopening Moncure Quarry

When the Triangle Area got hot, growth towards southern Wake County and Jordan Lake expanded rapidly. That led to the decision to reopen Moncure Quarry as a 250,000 ton per year location to cover the southern-most markets of the growing company. That reopening was the factor in the company never going under two million tons per year again.

1990 – Nash County Quarry Opening

Finding aggregate deposits can sometimes be as difficult as finding a needle in a haystack. For years, geologists had searched for quality deposits in Nash County without success. Then, in 1988, Wake Stone geologist David Lee was prospecting in the middle of a pine plantation near Interstate 95 north of Rocky Mount. He found what had eluded other geologists and, in doing so, gave Wake Stone the inside track on the county’s first quarry. Nash County is unique among the company’s operations. The other four locations sell most of their products in a two to three county territory. Nash County ships to customers in 25 Eastern North Carolina counties. The market’s size has made it necessary for Wake Stone to adopt new marketing approaches for the quarry. Hiring of the new crew caused a new milestone for the company – 100 employees.

The Booming 1990’s

The mid-1980’s were some good years and changes in the Triangle area took the company to a higher level. But the opening of a fourth location in 1990/91 and a very hot local and US economy changed the company significantly. In, addition, some very large jobs added to the construction aggregates market: the widening of I64/264, the I440 Beltline, and the addition of a runway at RDU Airport, in all of which Wake Stone participated. At the beginning of the decade we had doubled in size to a two million ton-per-year, 50-employee company. By the end of the 1990’s, we were a five million ton-per-year, 100-employee company. And we were ready to open a new location.

2000 – North Myrtle Beach Quarry

Locating and acquiring a viable hard rock deposit is very difficult, but finding mineable marine limestone in the Carolinas is even harder. Since the late 1980’s we had searched for a South Carolina site in high-growth Horry County. Finally, in 2000, we were able to purchase 400 acres on SC Highway 9, fifteen miles west of North Myrtle Beach. In addition, we negotiated a mineral lease for 1,100 acres adjacent to our property with International Paper Company. And by early 2002 we had excavated the initial pit, erected the crushing plant, and begun selling stone. Our timing could not have been better as the Myrtle Beach area exploded in residential development. Our fifth location took our headcount to a record level.

The New Millennium Begins

What an interesting decade! The burst of the dot.com boom period and the overblown computer software meltdown of the rollover from 1999 to 2000 wasn’t much, for Wake Stone anyway. And then, the 9/11 terrorist attack. Everyone remembers where they were when those planes hit the tower. The recession that followed was no surprise as we began a war with Iraq that seems to never end. As the decade continued into the second-half, Wake Stone enjoyed four of our biggest sales years – over twenty million tons during that time. Everything was going great until it wasn’t… and then the Great Recession hit in 2008/9. A great benefit to us during that time were some major new road construction jobs, including the northern section of I540 and the 64/264 East By-pass. The decade ended with a collapsing stock market, banks failing under the weight of foreclosed housing, auto manufacturer bankruptcies, and the Federal Reserve Bank system trying to reboot the American economy. Wake Stone survived. As all producers in our industry experienced, sales dropped to 50-60% of their prior levels. However, Wake Stone laid-off no employees. Although demand required only a 20-hour work week at all locations, our employees all earned 40 hour checks. And their benefits continued: health care, profit sharing and annual raises in their rates. At Wake Stone, we have enjoyed incredible employee loyalty, much of that from the loyalty of the owners to their employees. No time period solidified the confidence in the Company than those difficult recession years. For the last half of our fifty-year history, our average employee has been with the company for 15 years. Important to the continuity of the family business is family. Three more of the third generation joined the Company at the end of the decade, Bose Bratton, Hunter Bratton, and John Bratton Doak.

2012/13 – North Myrtle Beach Agricultural Products

After ten years of mining the NMB deposit, it became evident that the chemical properties of the limestone deposit would allow us to expand our product line beyond the construction materials we produce at all operations. In 2013 we constructed an AgLime processing plant to produce high grade calcium products for the agricultural and landscaping industries. Sales have grown to over 60,000 tons per year in coastal North and South Carolina counties. And in 2018 we began producing calcium feed supplements for poultry and swine. Those shipments are now exceeding 60,000 tons per year. This value-added product from a local source makes better sense than trucking the products from where our customers traditionally found them in western Virginia and eastern Tennessee.

2015 – Commercial Warehouse Development

With over 600 contiguous acres in the Knightdale ETJ, we have 200 more years of stone reserves. But we will not be mining many of those acres until the next century. A 50-acre parcel adjacent to Interstate 540 and some commercial/retail development seemed prime for an underserved warehouse market in the eastern part of Wake County. Working closely with the Town of Knightdale beginning in 2014, the Company developed Hinton Oaks Industrial Park, consisting of five warehouses and 525,000 square feet of storage. In 2020, five years after the first building was complete, the last building was completed and all five buildings were 100% leased. For the Town, this new development yielded over $35 million in tax base and hundreds of new jobs from ten great corporate tenants.

2019 – Expansion of Triangle Quarry

As part of their 25-year Plan, Vision 2040, the RDU Airport Authority (RDUAA) seeks to maximize their revenue to facilitate the growth in facilities and services at RDU International Airport. Beginning in 2015/16 they inquired of us as to whether a 105-acre parcel of their land adjacent to Triangle Quarry had stone reserves on it and was a viable quarry site. Over the next three years, we worked closely with RDUAA leadership to try to figure out how to get this done. And on March 1, 2019, the Authority signed a lease with Wake Stone to mine that property. Interested parties sued to stop the lease within weeks. The Wake County Superior Court sided with the Airport in October that the lease was legal and could proceed. The plaintiffs appealed to the NC Appeals Court, and that case is proceeding slowly. As of our 50th anniversary date, we have submitted our Triangle Quarry Mining Permit modification request and are optimistic that we could begin preparing the land for mining later in 2020. The quarry permit modification would allow us to continue to process and sell the stone from Triangle Quarry for another 25 years.

2021 – Wake Stone Property Company

In 2021 Company leadership decided to establish Wake Stone Property Company, a separate turn-key real estate company, to focus on development, management, and investment in and around the markets served by Wake Stone Corporation. The Property Company has expanded Hinton Oaks Industrial Park which will eventually consist of over one million square feet of best-in-class industrial warehouse space.

Continued Growth

The years since 1970 have been marked by steady and controlled growth for Wake Stone. This approach has allowed Wake Stone to remain lean and efficient. By designing and building all of its operations in-house, Wake Stone has provided continuing job opportunities for its employees and wisely managed its expenses. The average Wake Stone employee has been with the company for 15 years. They have helped maintain the family atmosphere that goes back to the beginning. With their continued support, a strong customer base, ample stone reserves and the continued economic growth of the Carolinas, Wake Stone is well positioned for the next 50 years and beyond.